Deck Plywood

Description

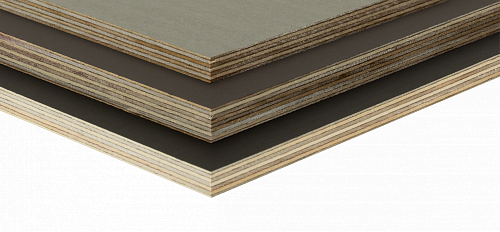

Film faced plywood of high quality represented at the market under the brand Deck is manufactured on the basis of Exterior birch plywood coated with film made of high density paper, impregnated with phenol-formaldehyde resin. Another option is the panel overlaid with modified phenolic film. Its bright rich color does not fade when exposed to sunlight for continuous period of time and guarantees high visual quality of the laminated plywood. There is a variety of film colors available.

Multilayer structure of 100% birch plywood guarantees exceptional strength and stiffness of Deck laminated plywood as well as its high load-bearing capacity. WBP glue, used for production of the panels, has excellent bonding properties. Formaldehyde emission level complies with the requirements of E1, EPA TSCA Title VI (according to the results of WKI tests, the average value for Deck is 0,1 mg/h х m2)

Film faced plywood (F/F) is resistant to different environmental and chemical conditions. Overlaid panels are irreplaceable when wear-resistant surfaces are needed. High resistance to abrasion of the film and stiffness of birch plywood make this product very popular for decking during concrete construction. Other areas of application of the film faced plywood are bridge building, scaffolding, flooring and sheathing of trucks. Laminated plywood is also used for interior and exterior cladding, packaging, furniture manufacturing and advertisement hoardings.

Smooth durable phenolic film makes birch plywood more resistant to impacts and other forms of bruising. The overlaid surface of the panel is easy to clean. Resistance to abrasion of the film faced plywood from Russian manufacturer Group is approved by Taber Test. Water-resistant coating may be of different colors. A customer may choose the film density according to his needs. Edges of the film faced plywood are sealed with water-resistant acrylic paint, which significantly reduces moisture absorption of the wood panel.

Technical sheet

Specifications

Thicknesses, mm: | 6,5; 9; 12; 15; 18; 19; 21; 24; 27; 30; 35; 40 |

Sizes, mm: | 22440×1220 or 1220×2440, 2500×1250 or 1250×2500, 2500×1525, 1525×3050, cut-to-size |

Grades: | I/I |

Surface type: | F/F (smooth/smooth) |

Film density: | 120/120 g/m2; 120/220 g/m2, 220/220 g/ m2 |

The formaldehyde emission according to WKI reports:(limit value: 3,5 mg/h х m2): | 0,1 mg/h х m2 |

Surface characteristics

(Other film densities are available upon the agreement with a customer)

Type of surface | Type of surface | Film density, g/m2 | Taber revolutions* | Rolling wear** |

Deck | F/F | 120 | 400-450 rounds | 3500 |

Deck Pro | F/F | 220 | 700-750 rounds | 5000 |

* The films of other densities are availbale on request.

** Abrasion resistance is tested according to DIN 53799/EN 438.

*** Resistance to rolling wear is determined by a method corresponding to SS 923508.

Strength characteristics

Thickness of plywood, mm | Bending strength, MPa, mean value | Modulus of Elasticity, MPa, mean value | ||

perpendicular to the fiber | parallel to the fiber | perpendicular to the fiber | parallel to the fiber | |

6,5 | 60 | 85 | 4300 | 9500 |

9 | 65 | 85 | 5700 | 9000 |

12 | 60 | 80 | 6000 | 8500 |

15 | 60 | 80 | 6500 | 8500 |

18 | 75 | 70 | 7000 | 8500 |

19 | 70 | 70 | 7200 | 8000 |

21; 24; 27; 30 | 70 | 70 | 7000 | 8000 |

Applications

-

Concrete formworks

Thanks to being light and durable material with good strength properties, film faced birch plywood is irreplaceable for concrete formworks. High resistance to abrasion of film-faced plywood is approved by Taber Test.

-

Advertisement hoardings

Durability of birch plywood makes it perfect for outdoor advertising. The alternation of cross and long grain veneer reduces the chances of the wood deformation and makes it resistant to warping, cracking, and twisting when setting.

-

Caravans

Overlaid plywood is valued by the producers of caravans because it does not lose its properties in various conditions, even when influenced by water, chemicals or heavy use.