Anti-slip Wire Plywood

Description

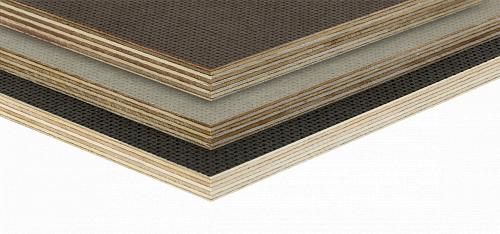

Anti-slip Wire is a special brand for non-slip birch plywood. Both sides of Anti slip Wire are overlaid with film which is made of high-density paper impregnated with phenol-formaldehyde resin. The slip-proof plywood has one side coated with smooth film and the other side with film having wire mesh surface that guarantees maximum anti-slip protection.

- Maximum slip resistance

- Improved hiding power and UV resistance

- High wear resistance (Taber test)

- Possibility of deep imprints

Smooth and slip-proof surfaces of film faced plywood withstand various weather and chemical conditions, while multi-layer structure of panels provides exceptional strength and makes them perfect for the production of wear-resistant surfaces. Anti-slip (F/W) plywood is used for flooring of trailers, vans, rail vehicles. In addition to transportation industry, our specific product with non-slip surface is also used for flooring when constructing warehouses, loading platforms, scaffolding, playgrounds. Slip-proof plywood has found its application in shipbuilding for decking of RORO ships.

Anti-slip Wire is manufactured on the basis of our Exterior birch plywood, i.e. Birch Exterior. Durability, strict thickness tolerances and resistance to banding make the base plywood very popular.

As a supplier of high-quality anti-slip plywood, we guarantees maximum slip resistance, minimum rolling wear (Rolling test) and high wear-resistance (Taber test) of the material.

As veneer is coated with film, only the defects of laminating are considered in grading. In addition, defects of wood which are noticeable outside are taken into account. Water-resistant coating is available in different colors and densities. Edges of the panel are sealed with water-resistant acrylic paint. You may contact our managers to buy Antislip Wire directly from producer.

Technical sheet

Specifications

Thicknesses, mm: | 6,5; 9; 12; 15; 18; 19; 21; 24; 27; 30; 35; 40 |

Sizes, mm: | 2440×1220 or 1220×2440, 2500×1250 or 1250×2500, 2500×1525, 1525×3050, cut-to-size |

Grades: | I/I |

Types of surface: | F/W (smooth/wire) |

Film density: | 120/120 g/m2; 120/220 g/m2, 220/220 g/ m2 |

The formaldehyde emission according to WKI reports: (limit value: 3,5 mg/h х m2): | 0,1-0,3 mg/h x m2 |

Surface characteristics

(Other film densities and patterns are available upon the agreement with a customer)

Product | Type of surface | Film density, g/m2 | Taber revolutions* | Rolling wear**

| Slip Resistance***

|

Antislip Wire | F/W | 120 | 400-450 | 3500 | R10 |

Antislip Wire | F/W | 220 | 750-800 | 5000 | R12 |

The films of other densities are availbale on request.

* Abrasion resistance is tested according to DIN 53799/EN 438

** Resistance to rolling wear is determined by a method corresponding to SS 923508.

*** Slip resistance is tested according to DIN 51130.

Strength characteristics

Thickness of plywood, mm | Bending strength, MPa, mean value | Modulus of Elasticity, MPa, mean value | ||

perpendicular to the fiber | parallel to the fiber | perpendicular to the fiber | parallel to the fiber | |

6,5 | 60 | 85 | 4300 | 9500 |

9 | 65 | 85 | 5700 | 9000 |

12 | 60 | 80 | 6000 | 8500 |

15 | 60 | 80 | 6500 | 8500 |

18 | 75 | 70 | 7000 | 8500 |

19 | 70 | 70 | 7200 | 8000 |

21; 24; 27; 30 | 70 | 70 | 7000 | 8000 |

Applications

-

Production of buses

Birch plywood has found wide application in transport industry. Film faced plywood with anti-slip pattern is very popular when it comes to buses floors, due to its non-slippery properties and resistance to abrasion.

-

Sheathing and flooring of trailers

Film faced plywood has longer durability and high wear resistance. It is easy to clean and resistant to commonly used chemicals. Anti-slip pattern on the wear surface of plywood for trailers floors guarantees safety of cargo during transportation.

-

Caravans

Overlaid plywood is valued by the producers of caravans because it does not lose its properties in various conditions, even when influenced by water, chemicals or heavy use.

-

Pedestrian bridges

Being able to withstand various weather conditions, birch plywood overlaid with wear-resistant phenolic film is perfect for exterior use. Thanks to anti-slip pattern of the film, Antislip prevents skidding even when its surface is wet.